How to Properly Inspect and Calibrate Dwyer Sensors

Posted on: 30/10/2025

In BMS, HVAC, and industrial automation systems, Dwyer sensors play a crucial role in measuring and controlling parameters such as pressure, temperature, flow, and humidity. However, to ensure the devices operate accurately and reliably, regular inspection and calibration are essential.

1. Why Regular Calibration of Dwyer Sensors Is Important

Calibration is the process of comparing a sensor’s measurement with a high-accuracy reference standard to detect deviations and adjust the device accordingly.

For Dwyer sensors, regular calibration provides multiple benefits:

-

Maintains measurement accuracy throughout the product’s lifecycle.

-

Prevents accumulated errors that could lead to incorrect system control.

-

Extends device lifespan and reduces replacement or maintenance costs.

-

Ensures stable operation of HVAC, BMS, or production systems.

-

Complies with ISO, ASHRAE, or GMP standards in engineering and industrial applications.

2. When Should You Check and Calibrate Dwyer Sensors?

Calibration should be performed at specific intervals or under certain conditions, such as:

-

Periodic schedule (e.g., every 6–12 months, depending on system criticality).

-

After installation, long-term operation, or maintenance.

-

When measurement results show inconsistencies or abnormal readings.

-

When sensors are exposed to extreme environmental or mechanical stress.

-

Engineers may shorten the calibration cycle for systems where safety and precision are top priorities.

3. Preparation Before Calibrating Dwyer Sensors

Before starting the calibration process, ensure the following steps:

-

Disconnect the power supply and pressure source connected to the sensor.

-

Use certified calibration equipment such as a pressure calibrator, manometer, or dry block calibrator.

-

Prepare a data log sheet to record comparison results.

-

Verify the sensor’s label, model, and measuring range (e.g., Dwyer 628 Series, 673 Series, TE Series, etc.).

Maintain a stable calibration environment, avoiding vibration or sudden temperature changes.

4. Calibration Procedure for Dwyer Sensors

Step 1: Preliminary Inspection

-

Check physical condition: cables, connectors, and sensor body.

-

Clean the sensing port to remove dust or residues.

-

Ensure normal operation with no signal drift or output errors.

Step 2: Connect to Calibration Equipment

Connect the sensor to a reference pressure or temperature source.

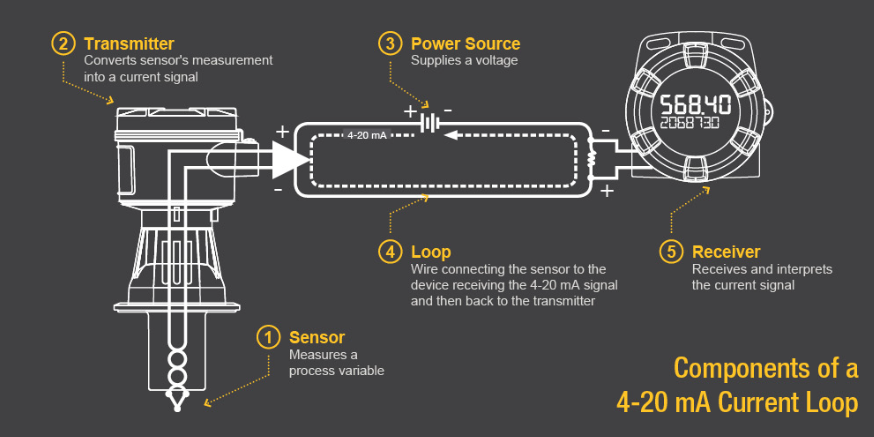

Verify that the output signal (4–20 mA or 0–10 VDC) is accurately read by the reference device.

Step 3: Compare and Record Values

Set reference values at several points (e.g., 0%, 50%, and 100% of full scale).

Record deviations between the sensor reading and the reference value.

If deviations exceed the acceptable range (typically ±0.5% F.S), proceed with adjustment.

Step 4: Adjust the Sensor Output

For electronic Dwyer sensors (e.g., 628, 673, TE Series): use software or fine-tuning potentiometers (Zero/Span).

For mechanical or analog sensors: perform manual adjustments as per manufacturer instructions.

Step 5: Recheck and Label Calibration

After adjustment, re-test the full measuring range to confirm accuracy.

Record calibration results, date, and technician information.

Attach a calibration verification label to the device.

5. Important Notes During Calibration

-

Only use calibration tools certified under international standards (ISO/IEC 17025).

-

Avoid performing calibration in environments with vibration, humidity, or dust.

-

If deviation is excessive, consider replacing the sensor for safe operation.

-

If lacking proper tools or expertise, send the device to a Dwyer-authorized service center.

6. Dwyer Sensor Inspection & Calibration Service by DLK Vietnam

As the official distributor of Dwyer Instruments in Vietnam, DLK Vietnam not only supplies original Dwyer sensors for pressure, temperature, flow, and humidity measurement but also provides professional calibration and inspection services nationwide.

DLK offers:

-

Calibration of Dwyer sensors to American standards.

-

Detailed calibration reports and certificates.

-

On-site maintenance and technical consultation.

-

Genuine replacement parts with CO–CQ documentation.

DLK Vietnam is committed to helping businesses maintain accurate measurement, optimize system performance, and minimize operational errors.