CMT200 – Dwyer Differential Pressure Sensor and Its Role in Modern BMS Systems

Posted on: 10/10/2025

Discover the Dwyer CMT200 differential pressure sensor – a high-precision, stable pressure measuring device that enhances airflow control and energy efficiency in modern BMS–HVAC systems

In modern smart buildings, controlling differential pressure between zones not only ensures operational efficiency but also directly impacts air quality and system safety. One of the most important devices in this process is the Dwyer CMT200 differential pressure sensor – a reliable measurement solution widely used in Building Management Systems (BMS).

1. What is a BMS, and why are sensors essential?

In modern buildings, commercial centers, or hospitals, a BMS (Building Management System) is considered the “central brain” that monitors and controls the operation of all technical systems, including:

-

Heating, Ventilation, and Air Conditioning (HVAC)

-

Lighting

-

Elevators

-

Water and energy systems

For these systems to operate accurately, measurement sensors are the foundation. They continuously provide real-time data on temperature, humidity, pressure, and flow rate, allowing the BMS controller to make automatic and precise decisions. Among them, differential pressure sensors—such as the Dwyer CMT200—are indispensable for maintaining proper airflow control, protecting cleanrooms, and ensuring balanced pressure throughout the entire system.

2. What is a differential pressure sensor?

A differential pressure sensor is a device used to measure the difference in pressure between two points in an air or liquid system.

For example:

-

Comparing pressure between the inlet and outlet of an air filter.

-

Monitoring pressure differences between a cleanroom and a corridor.

-

Controlling duct pressure to adjust fan speed.

When the pressure difference exceeds the set threshold, the BMS automatically adjusts or sends an alarm—ensuring performance, safety, and system stability.

3. Introduction to the Dwyer CMT200 Differential Pressure Sensor

The Dwyer CMT200 is a high-performance differential pressure sensor specifically designed for HVAC and BMS applications. It is manufactured by Dwyer Instruments – a globally recognized U.S. brand specializing in measuring devices for pressure, flow, temperature, and humidity.

Key Technical Specifications:

-

Measurement range: ±25 Pa to ±2500 Pa (depending on model)

-

Output signal: 4-20mA / 0-10V / Modbus (optional)

-

Accuracy: ±1% of full scale

-

Power supply: 24VDC

-

Operating temperature: -10°C to +50°C

-

Housing material: Flame-retardant ABS plastic with high durability

Main Features:

-

Extremely accurate and stable pressure measurement over time.

-

Zero and Span adjustment directly on the sensor body.

-

Supports Modbus RTU digital communication – fully compatible with BMS.

-

Compact design for easy installation in control panels or air ducts.

-

Excellent noise resistance and stable operation in fluctuating electrical environments.

4. Applications of the CMT200 in BMS and HVAC Systems

1. Cleanrooms

In hospitals, operating rooms, pharmaceutical factories, or electronics manufacturing facilities, controlling pressure differentials between areas is mandatory to prevent dust, bacteria, or toxic gases from entering. The Dwyer CMT200 continuously measures pressure differences between cleanrooms and corridors, ensuring a stable positive pressure environment.

2. Central HVAC Systems

The CMT200 is used for:

-

Monitoring differential pressure across fans.

-

Detecting clogged air filters (when pressure difference increases abnormally).

-

Controlling duct pressure to optimize fan speed and energy consumption.

The result is a quieter, more energy-efficient HVAC system with extended equipment lifespan.

3. Industrial Plants and Laboratories

In production environments that require stable compressed air or clean air pressure, the CMT200 is a reliable choice thanks to its high sensitivity and fast calibration capability.

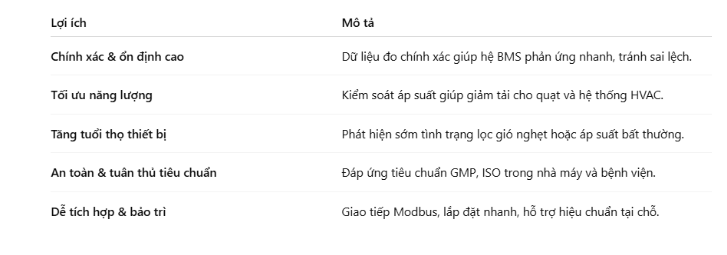

5. Benefits of Using the Dwyer CMT200 in BMS Systems

6. Tips for Selecting and Installing the CMT200 Differential Pressure Sensor

-

Determine the correct pressure range (Pa, kPa, bar, etc.).

-

Install in a location free from vibration, high temperature, or turbulent airflow.

-

Calibrate every 6–12 months to maintain measurement accuracy.

-

Connect to the BMS or PLC controller using standard shielded industrial cables.

DLK recommends using genuine Dwyer pressure tubing accessories to ensure the most stable signal transmission.

7. DLK – Official Dwyer Distributor in Vietnam

DLK Vietnam is the official distributor of Dwyer measuring instruments, providing comprehensive solutions for:

-

BMS – HVAC – Industrial plants

-

Product range: pressure, temperature, humidity, and flow sensors, Honeywell valves, and Kometer equipment

DLK not only supplies equipment but also offers technical consultation, installation guidance, and calibration support, helping customers achieve stable operations and optimal energy efficiency.

8. Conclusion

In the context of increasing emphasis on automation and energy efficiency, selecting a high-quality differential pressure sensor is essential. The Dwyer CMT200 offers outstanding accuracy, durability, and flexible connectivity—helping BMS and HVAC systems operate intelligently, reliably, and sustainably.