Pressure and Flow Control Solutions in HVAC Systems

Posted on: 02/04/2025

Controlling pressure and flow in HVAC systems helps optimize performance, save energy, and ensure a comfortable working environment. Solutions such as control valves, pressure sensors, and flow regulators help maintain stable operation and reduce equipment wear.

1. Introduction to DLK and the Role of Pressure and Flow Control

DLK is a leading provider of pressure and flow control solutions for HVAC systems. HVAC systems play a critical role in maintaining a stable working environment, optimizing operational efficiency, and reducing energy consumption.

-

Pressure and flow directly impact air quality: If the pressure is too high or too low, the system may not operate efficiently, leading to energy waste.

-

Flow control helps optimize operating costs: Ensuring stable water and airflow helps cooling and heating systems operate smoothly.

-

Protects equipment and extends system lifespan: Unstable pressure can damage critical components within the HVAC system.

2. Dwyer Pressure Sensors and Their Applications in HVAC

2.1. What is a Pressure Sensor? A pressure sensor is a device that measures the pressure of liquids or gases in an HVAC system. It helps monitor and adjust pressure to ensure the system operates optimally. (HVAC Term: Pressure Transducer, Pressure Transmitter)

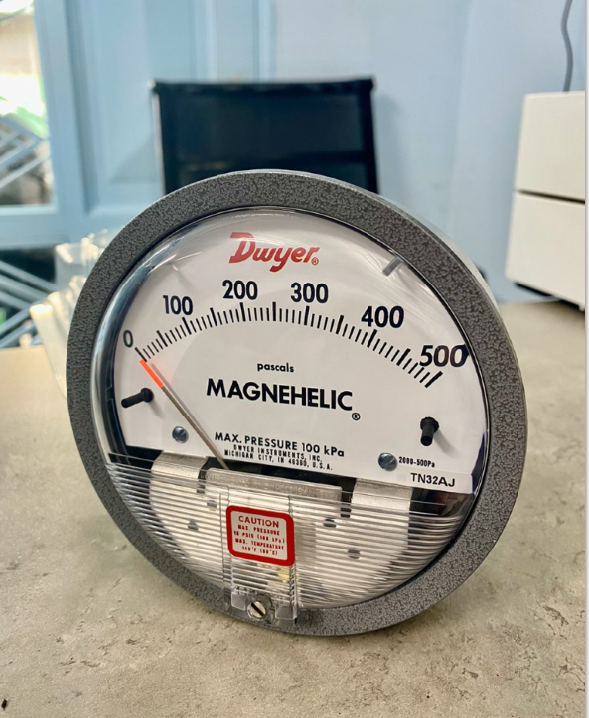

2.2. Common Types of Dwyer Pressure Sensors Dwyer is a leading brand of pressure sensors with high accuracy. Some popular sensor series include:

-

Static Pressure Sensors: Used in air conditioning systems to control pressure in air ducts. (HVAC term: Duct Static Pressure Sensor)

Series 628

-

Differential Pressure Sensors: Help measure the pressure difference in air filtration systems and clean rooms. (HVAC Term: Differential Pressure Transmitter)

Series 2000

2.3. Benefits of Using Dwyer Pressure Sensors

-

High accuracy helps control pressure effectively.

-

Minimizes technical problems and optimizes energy consumption.

-

Compatible with many automation systems.

(Image: A photo showing a Dwyer differential pressure sensor installed in an air duct. Ideally, show the Magnehelic gauge or a digital transmitter. Caption: "Dwyer Differential Pressure Sensor Monitoring Airflow")

3. Application of Kometer Flow Measurement Devices in HVAC

3.1. Why is Flow Control Necessary in HVAC Systems? Water and airflow have a significant impact on the operational efficiency of an HVAC system. If not properly controlled, energy can be wasted, and cooling or heating performance can be reduced.

3.2. Types of Kometer Flow Measurement Devices Kometer offers high-quality flow measurement devices, such as:

-

Water Flowmeters: Used in HVAC water supply and drainage systems to control cooling water flow. (HVAC term: Flow Meter)

-

Airflow Sensors: Help control airflow in air conditioning systems. (HVAC term: Airflow Sensor, Airflow Meter, Anemometer)

3.3. Benefits of Kometer Flow Measurement Devices

-

Ensure stable flow, helping the HVAC system operate efficiently.

-

Reduce water and air leaks, optimizing operating costs.

-

Easy integration with automatic control systems.

4. Honeywell Control Valves and Their Role in HVAC Systems

4.1. The Role of Control Valves in HVAC Control valves help control the flow of water and air in HVAC systems, ensuring the system operates as required. (HVAC Term: Control Valve)

4.2. Common Types of Honeywell Control Valves Honeywell offers many high-quality control valves, including:

-

Solenoid Valves: Used to automatically open/close water or airflow. (HVAC/Automation Term: Solenoid Valve)

-

Linear Control Valves: Adjust the flow rate to the desired level. (HVAC Term: Modulating Control Valve)

4.3. Benefits of Honeywell Control Valves

-

Accurately adjust flow, helping to optimize the operation of the HVAC system.

-

Reduce energy consumption by maintaining stable flow.

-

Easy integration with central control systems. (Automation term: BAS/BMS Integration)

5. Guide to Selecting Pressure and Flow Control Equipment for HVAC

5.1. How to Choose the Right Pressure Sensor

-

Determine the Pressure Range: Choose a device with a range suitable for the HVAC system.

-

Ability to Withstand Harsh Environments: Some sensors need to be moisture-proof and dust-proof.

-

Ability to Integrate with Control Systems: The sensor must have a suitable signal transmission protocol (e.g., 4-20mA, Modbus). (Automation Terms: 4-20mA Analog Output, Modbus Communication)

5.2. How to Choose the Right Flow Measurement Device

-

Choose the Type of Meter According to the Fluid: Water, air, or steam.

-

Easy Integration with the Central Control System.

-

Consider Accuracy and Flow Range.

5.3. How to Choose the Right Control Valve

-

Determine the Type of Valve Suitable for the Application.

-

Choose a Valve with Accurate Flow Control Capability.

-

Ensure High-Pressure Resistance.

6. Optimizing HVAC Systems with Sensors, Control Valves, and Flow Measurement Devices

6.1. How to Implement an Effective Control System

-

Build an automatic monitoring system to continuously track pressure and flow. (Automation Term: Building Automation System (BAS), Building Management System (BMS))

-

Install equipment at critical locations in the HVAC system.

-

Combine Dwyer sensors, Kometer measurement devices, and Honeywell valves to achieve optimal performance.

6.2. Maintenance and Periodic Inspection

-

Clean sensors and measuring devices periodically to avoid errors.

-

Inspect and calibrate equipment periodically to ensure accuracy.

-

Maintain control valves to maintain stable operation.

7. Conclusion

Controlling pressure and flow in HVAC systems is crucial to ensure operational efficiency, save energy, and protect equipment. DLK provides optimal solutions with Dwyer sensors, Kometer flow measurement devices, and Honeywell control valves to help customers achieve an efficient and durable HVAC system.

If you need further advice on pressure and flow control solutions, contact DLK for the best support!

DLK Trading Service Company Limited

Address: G6/14 Tran Van Giau, Le Minh Xuan Ward, Binh Chanh District, Ho Chi Minh City

Office: 111/7 Vuon Lai, Phu Tho Hoa Ward, Tan Phu District, Ho Chi Minh City

Website: https://dlk.com.vn/

Email: info@dlk.com.vn

Hotline: 070 357 0101 – 093 279 2697