Controlling Temperature in Paint Booth Heat Exchange Systems

Posted on: 09/07/2025

Jaguar. Ford. Ferrari. Three iconic automakers with storied racing pedigrees that have produced some of the fastest and most beautiful cars in the world—each draped in their signature paint color: British Racing Green, Ford's Grabber Blue, and Ferrari's Rosso Corsa.

Beyond adding personality and character, a car’s paint serves a critical function: protecting the body, frame, and internal components from environmental damage. It prevents rust and corrosion from deteriorating the raw materials underneath. Early automotive finishes were hand-applied by craftsmen such as furniture makers and carriage builders, using varnish primers and oil-based enamel paints. These finishes had low opacity and required multiple coats and long drying times. Despite the effort, they would soon become brittle and chip away.

💡 Did you know? Before the invention of spray painting technology in the 1920s, finishes were applied by brushing, dipping, or even pouring paint onto car parts. (Eastwood)

Optimizing Paint Application – The Role of Temperature Control

The key to achieving a flawless paint job lies in controlling every possible variable. Enter the paint booth—a controlled environment where temperature, humidity, and airflow are regulated to optimize paint delivery and curing. Not only do atmospheric conditions need control, but the temperature of the paint itself plays a vital role in its viscosity. If the paint is too cold and thick, it won’t flow correctly through the sprayer; too warm and thin, and it won’t deliver adequate coverage.

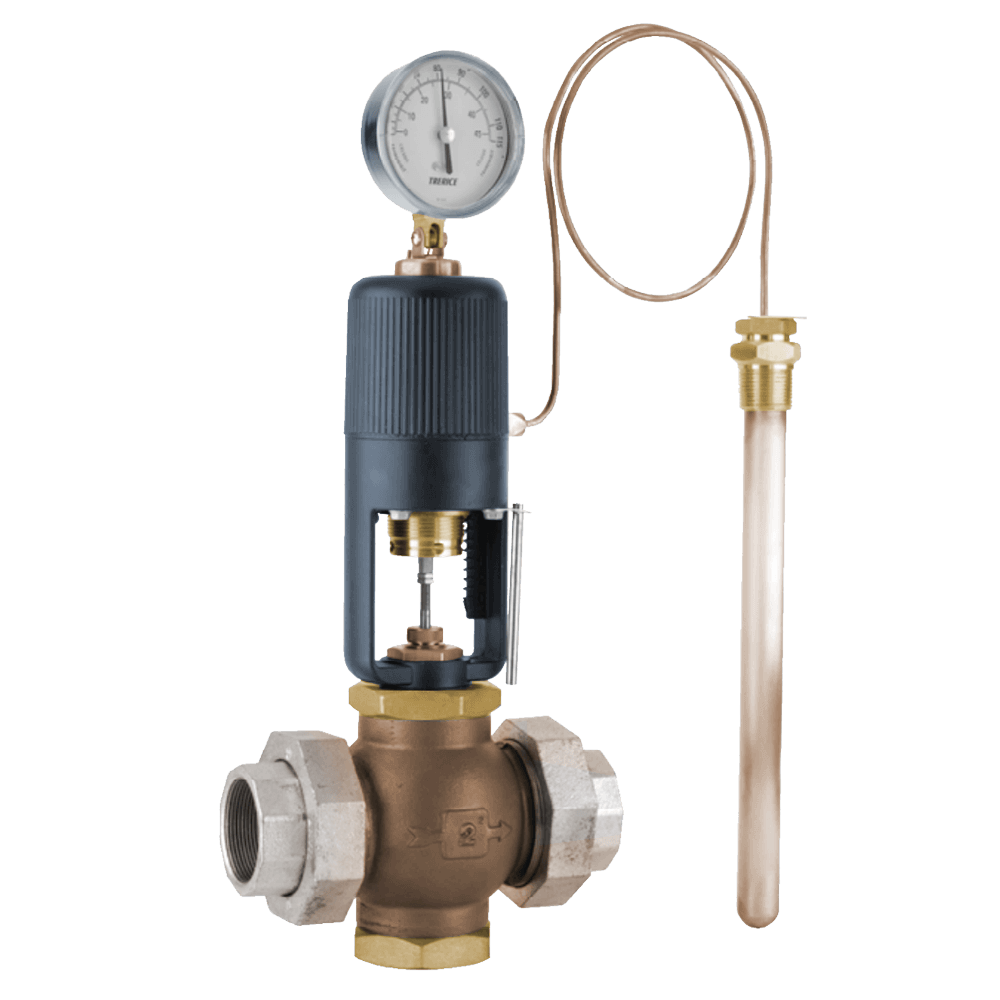

Self-Acting Temperature Control Valve – Series 38R

Advanced paint booths often use heat exchange systems, where warm or cold water circulates through a series of coils or lines inside a tank, heating or cooling the surrounding liquid—in this case, the paint. This process ensures that the paint reaches the ideal temperature right at the nozzle.

The Series 38R self-acting temperature control valve is the ideal solution for automatically monitoring and regulating temperatures in paint booth heat exchange systems. It features a heavy-duty, die-cast aluminum fail-safe actuator and over-range protection, delivering reliable, long-lasting performance. Since it requires no external power source, installation is straightforward and cost-effective.

Self-Acting Temperature Control Valve, Series 38R

DLK Trading Service Company Limited

-

Address: G6/14 Tran Van Giau, Le Minh Xuan Commune, Binh Chanh District, HCMC

-

Office: 111/7 Vuon Lai, Phu Tho Hoa Ward, Tan Phu District, HCMC

-

Website: https://dlk.com.vn

-

Email: info@dlk.com.vn

-

Hotline: 070 357 0101 – 093 279 269